Small businesses in Dubai are increasingly leveraging 3D printing technology to enhance their operations, reduce costs, and improve product offerings.

The use of 3D printed spare parts presents numerous opportunities for small enterprises to stay competitive and agile in a fast-paced market. Here, we explore the various ways small businesses in Dubai can benefit from 3D printed spare parts.

Cost Reduction

Lower Production Costs

One of the most significant benefits of 3D printing Dubai, for small businesses is the reduction in production costs. Traditional manufacturing methods often require expensive molds and tooling, which can be prohibitively expensive for small enterprises. With 3D printing, businesses can produce spare parts without the need for these costly tools, significantly lowering the initial investment.

Reduced Inventory Costs

3D printing allows for on-demand production, which means small businesses no longer need to maintain large inventories of spare parts. This reduces storage costs and minimizes the risk of excess inventory becoming obsolete. By printing parts as needed, businesses can better manage their inventory and reduce waste.

Faster Time to Market

Rapid Prototyping

3D printing enables rapid prototyping, allowing small businesses to quickly design, test, and iterate on new parts. This accelerates the product development cycle, enabling businesses to bring new products to market faster. The ability to rapidly prototype and refine designs ensures that final products are of higher quality and meet customer needs more effectively.

On-Demand Production

For small businesses, the ability to produce spare parts on demand is a game-changer. This flexibility means that companies can respond quickly to customer needs and market changes. On-demand production reduces lead times and ensures that spare parts are available when needed, improving customer satisfaction and loyalty.

Customization and Personalization

Tailored Solutions

3D printing technology offers unparalleled customization capabilities. Small businesses can create spare parts tailored to specific customer requirements, enhancing the overall value proposition. This level of personalization can set businesses apart from competitors, attracting a loyal customer base seeking unique and customized solutions.

Niche Markets

Small businesses can use 3D printing to tap into niche markets that require specialized spare parts. By offering customized solutions, businesses can cater to specific industries or applications that larger manufacturers might overlook. This focus on niche markets can lead to higher margins and a stronger market presence.

Innovation and Flexibility

Design Freedom

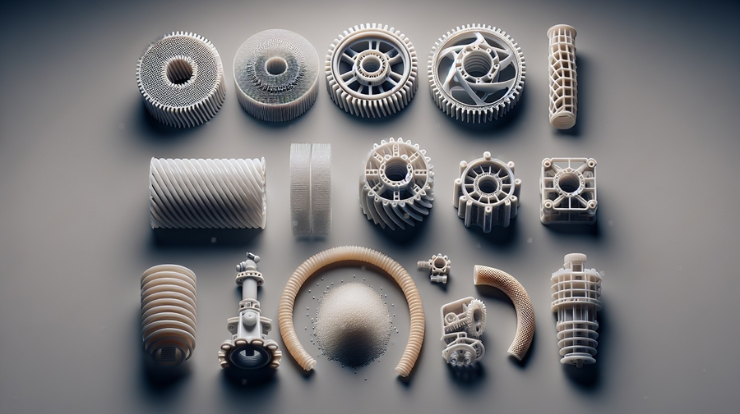

3D printing provides small businesses with the freedom to innovate and experiment with new designs. Traditional manufacturing methods often impose design limitations, but 3D printing allows for the creation of complex geometries and intricate details. This design freedom encourages innovation and enables businesses to develop unique products that stand out in the market.

Flexibility in Production

The versatility of 3D printing allows small businesses to quickly adapt to changing market demands. Whether it’s modifying a design, switching materials, or scaling production up or down, 3D printing offers the flexibility needed to stay competitive. This agility is particularly beneficial for small businesses that need to pivot quickly in response to new opportunities or challenges.

Improved Supply Chain Management

Localized Production

3D printing can decentralize manufacturing, allowing small businesses to produce spare parts locally. This reduces reliance on global supply chains, which can be vulnerable to disruptions. Localized production enhances supply chain resilience, reduces lead times, and minimizes shipping costs, ultimately improving operational efficiency.

Reduced Lead Times

With 3D printing, small businesses can produce spare parts faster than traditional manufacturing methods.

Reduced lead times mean that businesses can respond more quickly to customer orders and maintenance needs, improving service levels and reducing downtime. This speed is particularly advantageous for industries where quick turnaround times are critical.

Sustainability and Environmental Benefits

Reduced Waste

3D printing is an additive manufacturing process, which means parts are built layer by layer. This approach generates significantly less waste compared to subtractive manufacturing methods that cut away material from a larger block.

For small businesses focused on sustainability, the reduced waste from 3D printing aligns with green initiatives and can lower material costs.

Energy Efficiency

Producing spare parts with 3D printing often consumes less energy than traditional manufacturing processes. Energy-efficient production methods contribute to lower operational costs and reduce the environmental footprint of small businesses. This commitment to sustainability can also enhance brand reputation and appeal to eco-conscious customers.

Enhanced Customer Experience

Immediate Availability

The ability to produce spare parts quickly ensures that small businesses can meet customer demands promptly. Immediate availability of parts enhances the customer experience, leading to higher satisfaction and repeat business. This reliability can be a key differentiator in competitive markets.

Post-Sale Support

Offering 3D printed spare parts allows small businesses to provide comprehensive post-sale support. Customers can easily obtain replacement parts, extending the lifespan of products and ensuring continued functionality. This level of support fosters customer loyalty and encourages positive word-of-mouth referrals.

Conclusion

The adoption of 3D printed spare parts presents a multitude of benefits for small businesses in Dubai. From cost reduction and faster time to market to customization, innovation, and improved supply chain management, 3D printing technology empowers small enterprises to stay competitive and agile.

By leveraging the advantages of 3D printed spare parts, small businesses can enhance their operations, better serve their customers, and thrive in an increasingly dynamic market.